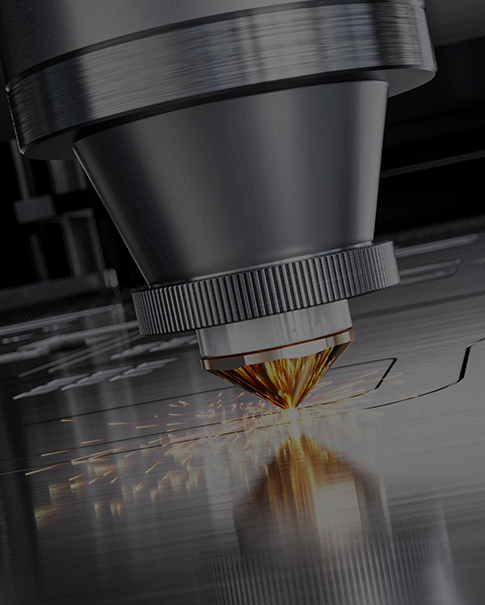

En el mundo de la fabricación de metales pesados, cortar acero dulce grueso (MS) con alta potencia y precisión siempre ha sido un desafío, hasta ahora. PENTA LASER tecnología de corte con zoom está redefiniendo lo que es posible, desbloqueando un rendimiento inigualable incluso para las aplicaciones más exigentes.

Recientemente, nuestros ingenieros demostraron con éxito un Sistema de corte por láser de 30 kW Equipada con tecnología de corte Zoom. La máquina corta sin esfuerzo. Acero dulce de 30 mm de espesor (MS) en un momento notable velocidad de 2,6 m/min, utilizando un gas mixtoProceso para una calidad óptima del borde y estabilidad del proceso.

Este rendimiento de corte demuestra el gran avance de la tecnología láser de fibra. En comparación con los cabezales de corte tradicionales de alta potencia, la tecnología de zoom de PENTA ajusta automáticamente el tamaño y la posición del punto focal en tiempo real, garantizando una calidad de haz perfecta para cualquier espesor y tipo de material.

Mayor velocidad de corte: Al optimizar dinámicamente el haz, la velocidad de corte aumenta significativamente, lo que le permite ahorrar tiempo y costos.

Bordes más limpios: El corte con zoom produce bordes más suaves y precisos incluso en placas gruesas.

Rango de aplicación más amplio: Desde láminas delgadas hasta placas ultra gruesas, un solo cabezal lo hace todo.

Intervención reducida del operador: Los ajustes inteligentes reducen el tiempo de configuración y el riesgo de error humano.

A medida que las industrias buscan una mayor productividad y una mejor calidad, los láseres de alta potencia con óptica inteligente se convertirán en el estándar. PENTA LASER continúa innovando, combinando alta potencia (30kW) con óptica inteligente para ofrecer lo mejor de ambos mundos: velocidad y precisión.

Si su tienda busca mejorar sus capacidades de corte o si tiene curiosidad sobre cómo la tecnología de corte Zoom puede beneficiar su línea de producción, comuníquese con nuestro equipo hoy mismo para programar una demostración.

Corte con más inteligencia. Corte más rápido. Corte con PENTA.